Gilasi AG, gilasi antiglare fun nronu ifọwọkan

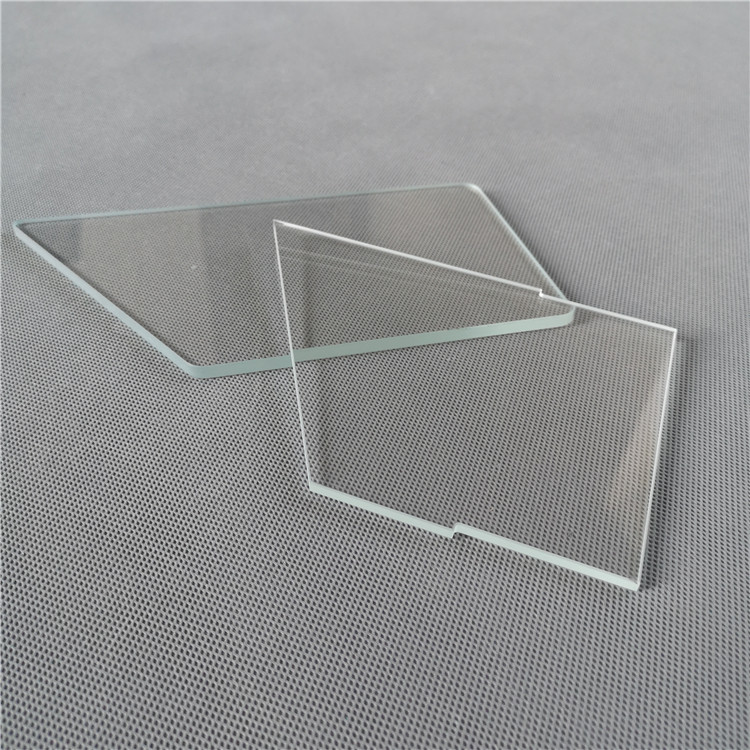

Imọ data

| Sisanra | ogidi nkan | spraying ti a bo | kemikali etching | ||||

| oke | isalẹ | oke | isalẹ | oke | isalẹ | ||

| 0.7mm | 0.75 | 0.62 | 0.8 | 0.67 | 0.7 | 0.57 | |

| 1.1mm | 1.05 | 1.15 | 1.1 | 1.2 | 1 | 1.1 | |

| 1.5mm | 1.58 | 1.42 | 1.63 | 1.47 | 1.53 | 1.37 | |

| 2mm | 2.05 | 1.85 | 2.1 | 1.9 | 2 | 1.8 | |

| 3mm | 3.1 | 2.85 | 3.15 | 2.9 | 3.05 | 2.8 | |

| 4mm | 4.05 | 3.8 | 4.1 | 3.85 | 4 | 3.75 | |

| 5mm | 5.05 | 4.8 | 5.1 | 4.85 | 5 | 4.75 | |

| 6mm | 6.05 | 5.8 | 6.1 | 5.85 | 6 | 5.75 | |

| Paramita | didan | aibikita | owusuwusu | gbigbe | irisi | ||

| 35±10 | 0.16 ± 0.02 | 17±2 | > 89% | ~1% | |||

| 50±10 | 0.13 ± 0.02 | 11±2 | > 89% | ~1% | |||

| 70±10 | 0.09 ± 0.02 | 6±1 | > 89% | ~1% | |||

| 90±10 | 0.07 ± 0.01 | 2.5 ± 0.5 | > 89% | ~1% | |||

| 110±10 | 0.05 ± 0.01 | 1.5 ± 0.5 | > 89% | ~1% | |||

| Idanwo ipa | Sisanra | iwuwo rogodo irin (g) | iga(cm) | ||||

| 0.7mm | 130 | 35 | |||||

| 1.1mm | 130 | 50 | |||||

| 1.5mm | 130 | 60 | |||||

| 2mm | 270 | 50 | |||||

| 3mm | 540 | 60 | |||||

| 4mm | 540 | 80 | |||||

| 5mm | 1040 | 80 | |||||

| 6mm | 1040 | 100 | |||||

| Lile | > 7H | ||||||

|

| AG spraying ti a bo | AG kemikali etching | |||||

| Idanwo anticorsion | Ifojusi NaCL 5%: | N/A | |||||

| Idanwo ọriniinitutu resistance | 60 ℃, 90% RH, awọn wakati 48 | N/A | |||||

| Abrasion igbeyewo | 0000 # irun irun fsteel pẹlu 100ogf, 6000cycles, 40cycles/min | N/A | |||||

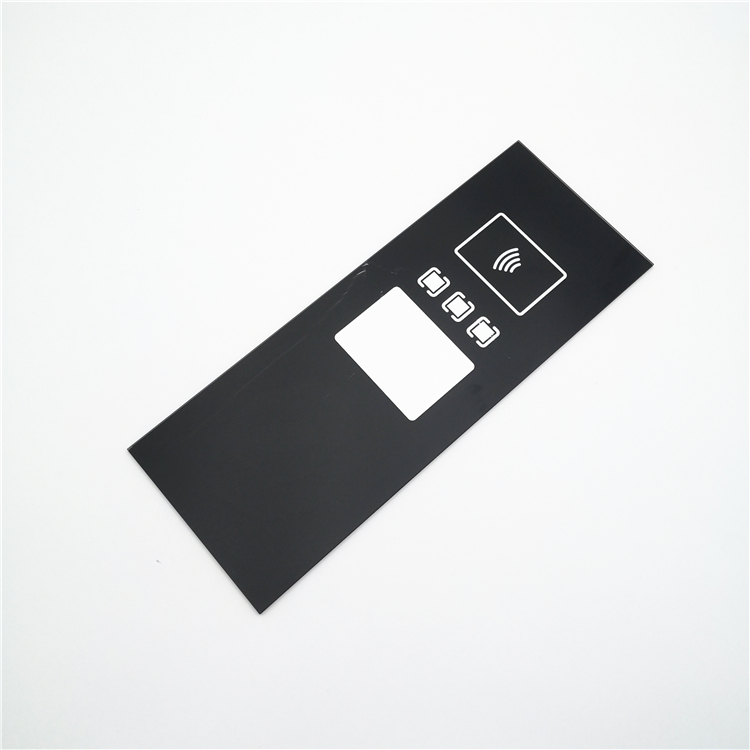

Ṣiṣẹda

Gilasi egboogi-glare, tọka si bi gilasi AG, jẹ iru gilasi kan pẹlu itọju pataki lori dada gilasi.Ilana naa ni lati ṣe ilana agbekọja didara giga ni ẹyọkan tabi awọn ẹgbẹ mejeeji lati jẹ ki o ni irisi kekere ju gilasi lasan, nitorinaa idinku kikọlu ti ina ibaramu, imudarasi alaye ti aworan, idinku irisi iboju, ati jẹ ki aworan di mimọ ati diẹ sii bojumu, gbigba awọn oluwo lati gbadun dara visual ipa.

Ilana iṣelọpọ ti gilasi AG ti pin si AG ti a bo sokiri ti ara ati etching kemikali AG

1. AG spraying gilasi

O tumọ si pe nipasẹ titẹ tabi agbara centrifugal, awọn patikulu bii silica sub-micron ti wa ni iṣọkan ti a bo lori dada gilasi nipasẹ ibon sokiri tabi atomizer disiki, ati lẹhin alapapo ati itọju imularada, ipele ti awọn patikulu ti ṣẹda lori gilasi. dada.Tan tan imọlẹ ti ina lati ṣaṣeyọri ipa anti-glare

Bi o ti n fun ifunpa lori oju gilasi, nitorina sisanra gilasi yoo nipọn diẹ lẹhin ti a bo.

2. AG kemikali etching gilasi.

O tọka si awọn lilo ti kemikali reactions.it nbeere kemikali bi hydrofluoric acid, hydrochloric acid, ati sulfuric acid to etching awọn gilasi dada lati didan to matt pẹlu micron patiku dada, eyi ti o jẹ abajade ti awọn ni idapo igbese ti ionization iwontunwosi, kemikali lenu, itu ati recrystallization, ion rirọpo ati awọn miiran aati.

Bi o ṣe n ṣe oju ilẹ gilasi, nitorina sisanra gilasi yoo jẹ tinrin diẹ ju ti iṣaaju lọ.

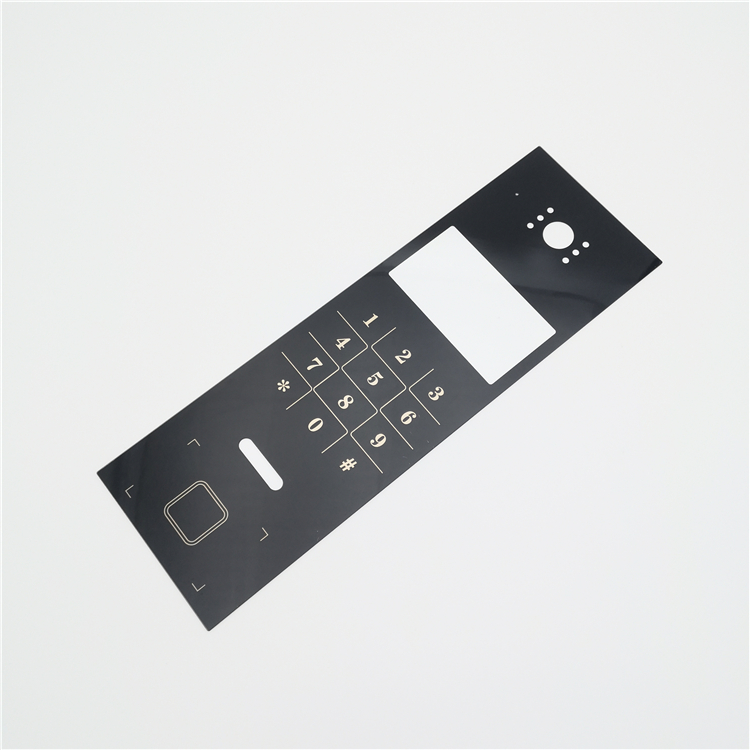

Fun idi-idaabobo adaṣe tabi EMI, a le ṣafikun ibora ITO tabi FTO.

Fun ojutu antiglare, a le gba ibora egboogi glare papọ lati ni ilọsiwaju iṣakoso iṣaro ina.

Fun ojutu oleophobic, ideri titẹ sita ika le jẹti o dara juapapo lati ni ilọsiwaju rilara ifọwọkan ati jẹ ki iboju ifọwọkan rọrun lati nu.

AG (egboogi glare) gilasi VS AR (egboogi reflective) gilasi, kini iyatọ, eyiti o dara julọ.ka siwaju

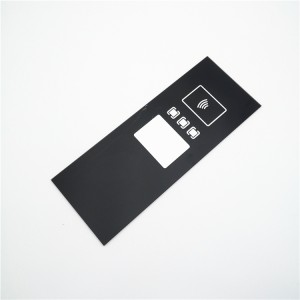

Jẹmọ elo

Kemikali sooro egboogi glare gilasi fun ile-ifọwọkan nronu

Gilaasi egboogi glare iwọn nla fun awọn iboju ifọwọkan ami oni nọmba

Awọn lẹnsi ideri gilasi ti kii ṣe didan fun iboju ifọwọkan lilọ kiri ọkọ ayọkẹlẹ